Transparent Display Technology

1. History OF OLED

The first

observations of electroluminescence in organic materials were in the early

1950s by A. Bernanose and co-workers at the Nancy-Université, France. They

applied high-voltage alternating current (AC) fields in air to materials such

as acridine orange, either deposited on or dissolved in cellulose or cellophane

thin films. The proposed mechanism was either direct excitation of the dye

molecules or excitation of electrons.

In 1960, Martin

Pope and co-workers at New York University developed ohmic dark-injecting

electrode contacts to organic crystals. They further described the necessary

energetic requirements (work functions) for hole and electron injecting

electrode contacts. These contacts are the basis of charge injection in all

modern OLED devices. Pope's group also first observed direct current (DC)

electroluminescence under vacuum on a pure single crystal of anthracene and on

anthracene crystals doped with tetracene in 1963using a small area silver

electrode at 400V. The proposed mechanism was field-accelerated electron

excitation of molecular fluorescence.

Pope's group

reported in 1965 that in the absence of an external electric field, the electroluminescence

in anthracene crystals is caused by the recombination of a thermalized electron

and hole, and that the conducting level of anthracene is higher in energy than

the exciton energy level. Also in 1965, W. Helfrich and W. G. Schneider of the

National Research Council in Canada produced double injection recombination

electroluminescence for the first time in an anthracene single crystal using

hole and electron injecting electrodes,the forerunner of modern double

injection devices. In the same year, Dow Chemical researchers patented a method

of preparing electroluminescent cells using high voltage (500–1500 V) AC-driven

(100–3000 Hz) electrically-insulated one millimetre thin layers of a

melted phosphor consisting of ground anthracene powder, tetracene, and graphite

powder.[ Their proposed mechanism involved electronic excitation at

the contacts between the graphite particles and the anthracene molecules.

Device

performance was limited by the poor electrical conductivity of contemporary

organic materials. This was overcome by the discovery and development of highly

conductive polymers.For more on the history of such materials, see conductive

polymers.

Electroluminescence

from polymer films was first observed by Roger Partridge at the National Physical

Laboratory in the United Kingdom. The device consisted of a film of

poly(n-vinylcarbazole) up to 2.2 micrometres thick located between two charge

injecting electrodes. The results of the project were patented in 1975 and

published in 1983.

The first diode

device was reported at Eastman Kodak by Ching W. Tang and Steven Van Slyke in

1987.This device used a novel two-layer structure with separate hole

transporting and electron transporting layers such that recombination and light

emission occurred in the middle of the organic layer. This resulted in a

reduction in operating voltage and improvements in efficiency and led to the

current era of OLED research and device production.

Research into

polymer electroluminescence culminated in 1990 with J. H. Burroughes et al. at the Cavendish Laboratory in

Cambridge reporting a high efficiency green light-emitting polymer based device

using 100 nm thick films of poly(p-phenylene vinylene).

2. Organic light-emitting diode (OLDE)

An organic

light emitting diode (OLED) is a light-emitting diode (LED) in

which the emissive electroluminescent layer is a film of organic compounds

which emit light in response to an electric current. This layer of organic

semiconductor material is situated between two electrodes. Generally, at least

one of these electrodes is transparent.

OLEDs are used in television set

screens, computer monitors, small, portable system screens such as mobile

phones and PDAs , watches, advertising,

information, and indication. OLEDs are also used in light sources for space

illumination and in largearea light-emitting elements. Due to their early stage

of development, theytypically emit less light per unit area than inorganic

solid-state based LED point-light sources.

An OLED display functions without a

backlight. Thus, it can display deep black levels and can be thinner and

lighter than liquid crystal displays. In low ambient light conditions such as

dark rooms, an OLED screen can achieve a higher contrast ratio than an LCD

using either cold cathode fluorescent lamps or the more recently developed LED

backlight.

There are two main families of

OLEDs: those based upon small molecules and those employing polymers. Adding

mobile ions to an OLED creates a Light-emitting Electrochemical Cell or LEC,

which has a slightly different mode of operation.

OLED displays can use either

passive-matrix (PMOLED) or active-matrix addressing schemes. Active-matrix

OLEDs (AMOLED) require a thin-film transistor backplane to switch each

individual pixel on or off, and can make higher resolution and larger size

displays possible.

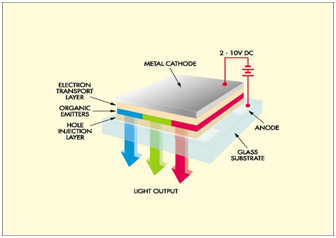

3. Architecture of OLEDs

3.1Substrate

(clear plastic, glass, foil)

The

substrate supports the OLED.

3.2Anode

(transparent)

The

anode removes electrons (adds electron "holes") when a current flows

through the device.

3.3 Organic

layer:

3.3.1Conducting

layer

This

layer is made of organic plastic molecules that transport "holes"

from the anode. One conducting polymer used in OLEDs is polyaniline.

3.3.2 Emissive layer

This layer is made of organic plastic

molecules (different ones from the conducting layer) that transport electrons

from the cathode; this is where light is made. One polymer used in the emissive

layer is polyfluorene.

3.4 Cathode

(may or may not be transparent depending on the type of OLED)

The

cathode injects electrons when a current flows through the device.

4.

AMOLED

Active-matrix OLED (active-matrix organic light-emitting diode )

AMOLED is a display technology for use

in mobile devices and televisions. Oled scribes a specific type of thin

film display technology in which organic compounds form

the electroluminescent material, and active matrix refers

to the technology behind the addressing of pixels.

Active matrix

(AM) OLED displays stack cathode, organic, and anode layers on top of another

layer – or substrate – that contains circuitry. The pixels are defined by the

deposition of the organic material in a continuous, discrete “dot” pattern.

Each pixel is activated directly: A corresponding circuit delivers voltage to

the cathode and anode materials, stimulating the middle organic layer. AM OLED

pixels turn on and off more than three times faster than the speed of

conventional motion picture film – making these displays ideal for fluid,

full-motion video.

5. Technical of AMOLED

Two primary TFT backplane technologies, poly-Silicon (poly-Si) and

amorphous-Silicon (a-Si) are used today in AMOLEDs.

Passive-Matrix

Structure Active Matrix Structure

AMOLED is a display technology for use in mobile devices and

televisions. Oled scribes a specific type of thin film display technology

in which organic compounds form

the electroluminescent material, and active matrix refers

to the technology behind the addressing of pixels.

TFT backplane technology is crucial in the fabrication of

AMOLED displays.

Two primary TFT backplane technologies, namely polycrystalline silicon (poly-Si)

and amorphous silicon (a-Si), are used today in AMOLEDs.

These technologies offer the potential for fabricating the active

matrix backplanes at low temperatures (below 150°C) directly onto flexible

plastic substrates for producing flexible AMOLED displays.

6.

Advantages of AMOLED

6.1 Lower cost in the future:

OLEDs can be printed onto

any suitable substrate by an inkjetprinter or even by screen printing,

theoretically making them cheaper to produce than LCD or plasma displays.

However, fabrication of the OLED substrate is more costly than that of a TFT

LCD, until mass production methods lower cost through scalability. Roll-roll

vapour-deposition methods for organic devices do allow mass production of

thousands of devices per minute for minimal cost, although this technique also

induces problems in that multi-layer devices can be challenging to make.

6.2 Light weight & flexible plastic

substrates:

OLED displays can be

fabricated on flexible plastic substrates leading to the possibility of

flexible organic light-emitting diodes being fabricated or other new

applications such as roll-up displays embedded in fabrics or clothing. As the

substrate used can be flexible such as PET., the displays may be produced

inexpensively.

6.3 Wider viewing angles & brightness: improved

OLEDs can enable a

greater artificial contrast ratio (both dynamic range pixel colours appear

correct and unshifted, even as the viewing angle approaches 90° from normal.and

static, measured in purely dark conditions) and viewing angle compared to LCDs

because OLED pixels directly emit light. OLED

6.4 Better power efficiency:

LCDs filter the light

emitted from a backlight, allowing a small fraction of light through so they

cannot show true black, while an inactive OLED element does not produce light

or consume power.

6.5 Response time:

OLEDs can also have a faster

response time thanstandardLCD screens. Whereas LCD displays are capable of

between 2 and 8 ms response time offering a frame rate of +/-200 Hz, an

OLED can theoretically have less than 0.01 ms response time enabling

100,000 Hz refresh rates.

6.6 High

Perceived Luminance

Perceived

luminance is 1.5 times higher than that of conventional lcd display

6.7 True

Colors

High

color gamut and no color shift by viewing angle and/or gray scales

6.8 Fast

Response

More

vivid and dynamic image quality is realized in moving pictures

7.

Disadvantages of AMOLED

7.1 Current costs:

OLED manufacture

currently requires process steps that make it extremely expensive.

Specifically, it requires the use of Low-Temperature Polysilicon backplanes;

LTPS backplanes in turn require laser annealing from an amorphous silicon

start, so this part of the manufacturing process for AMOLEDs starts with the

process costs of standard LCD, and then adds an expensive, time-consuming process

that cannot currently be used on large-area glass substrates.

7.2 Lifespan:

The biggest technical

problem for OLEDs was the limited lifetime of the organic materials. In

particular, blue OLEDs historically have had a lifetime of around 14,000 hours

to half original brightness (five years at 8 hours a day) when used for

flat-panel displays. This is lower than the typical lifetime of LCD, LED or PDP

technology—each currently rated for about 25,000 – 40,000 hours to half

brightness, depending on manufacturer and model. However, some manufacturers'

displays aim to increase the lifespan of OLED displays, pushing their expected

life past that of LCD displays by improving light out coupling, thus achieving

the same brightness at a lower drive current. In 2007, experimental OLEDs were

created which can sustain 400 cd/m2 of luminance for over

198,000 hours for green OLEDs and 62,000 hours for blue OLEDs.

7.3

Color balance issues:

Additionally, as the OLED

material used to produce blue light degrades significantly more rapidly than

the materials that produce other colors, blue light output will decrease

relative to the other colors of light. This differential color output change

will change the color balance of the display and is much more noticeable than a

decrease in overall luminance.This can be partially avoided by adjusting colour

balance but this may require advanced control circuits and interaction with the

user, which is unacceptable for some users. In order to delay the problem,

manufacturers bias the colour balance towards blue so that the display

initially .

7.4 Efficiency of blue OLEDs:

Improvements to the

efficiency and lifetime of blue OLEDs is vital to the success of OLEDs as

replacements for LCD technology. Considerable research has been invested in

developing blue OLEDs with high external quantum efficiency as well as a deeper

blue color. External quantum efficiency values of 20% and 19% have been

reported for red (625 nm) and green (530 nm) diodes,

respectively.However, blue diodes (430 nm) have only been able to achieve

maximum external quantum efficiencies in the range between 4% to 6%.

7.5 Water damage:

Water can damage the

organic materials of the displays. Therefore, improved sealing processes are

important for practical manufacturing. Water damage may especially limit the

longevity of more flexible displays.

7.6 Outdoor performance:

As an emissive display technology,

OLEDs rely completely upon convertingelectricity to light, unlike most LCDs

which are to some extent reflective; e-ink leads the way in efficiency with ~

33% ambient light reflectivity, enabling the display to be used without any

internal light source. The metallic cathode in an OLED acts as a mirror, with

reflectance approaching 80%, leading to poor readability in bright ambient

light such as outdoors. However, with the proper application of a circular

polarizer and anti-reflective coatings, the diffuse reflectance can be reduced

to less than 0.1%. With 10,000 fc incident illumination (typical test condition

for simulating outdoor illumination), that yields an approximate photopic

contrast of 5:1.

7.7 Power consumption:

While an OLED will

consume around 40% of the power of an LCD displaying an image which is

primarily black, for the majority of images it will consume 60–80% of the power

of an LCD – however it can use over three times as much power to display an

image with a white background such as a document or website. This can lead to

reduced real-world battery life in mobile devices.

7.8 Screen burn-in:

Unlike displays with a

common light source, the brightness of each OLED pixel fades depending on the

content displayed. The varied lifespan of the organic dyes can cause a

discrepancy between red, green, and blue intensity. This leads to image

persistence, also known as burn-in.

7.9 UV sensitivity:

OLED displays can be

damaged by prolonged exposure to UV light. The most pronounced example of this

can be seen with a near UV laser (such as a Bluray pointer) and can damage the

display almost instantly with more than 20 mW leading to dim or dead spots

where the beam is focused. This is usually avoided by installing a UV blocking

filter over the panel and this can easily be seen as a clear plastic layer on

the glass. Removal of this filter can lead to severe damage and an unusable

display after only a few months of room light exposure.

8. Applications of AMOLEDs

1.

TVs

2.

Cell Phone screens

3.

Computer Screens

4.

Keyboards (Optimus Maximus)

5.

Lights

6.

Portable Divice displays

8.1 AMOLED Televisions

Sony

·

Released XEL-1 in February

2009.

·

First OLED TV sold in stores.

·

11'' screen, 3mm thin

·

$2,500 MSRP

·

Weighs approximately 1.9 kg

·

Wide 178 degree viewing angle

·

1,000,000:1 Contrast ratio

8.2 Optimum Maximums Keyboard

•

Small

OLED screen on every key

•

113 OLED screens total

•

Each key can be programmed to preform a series of

functions

•

Keys can be linked to applications

•

Display notes, numerals, special symbols, HTML codes,

etc...

•

SD card slot for

•

storing

settings

9. Future Uses for AMOLED

9.1 Lightin

•

Flexible / bendable lighting

•

Wallpaper lighting defining new ways to light a space

•

Transparent lighting doubles as a window

9.2 Cell Phones

•

Nokia 888

9.3Transparent Car Navigation System on Windshield

•

Using Samsungs' transparent AMOLED technology

•

Heads up display

•

GPS system

9.4 Scroll Laptop

•

Nokia concept AMOLED Laptop